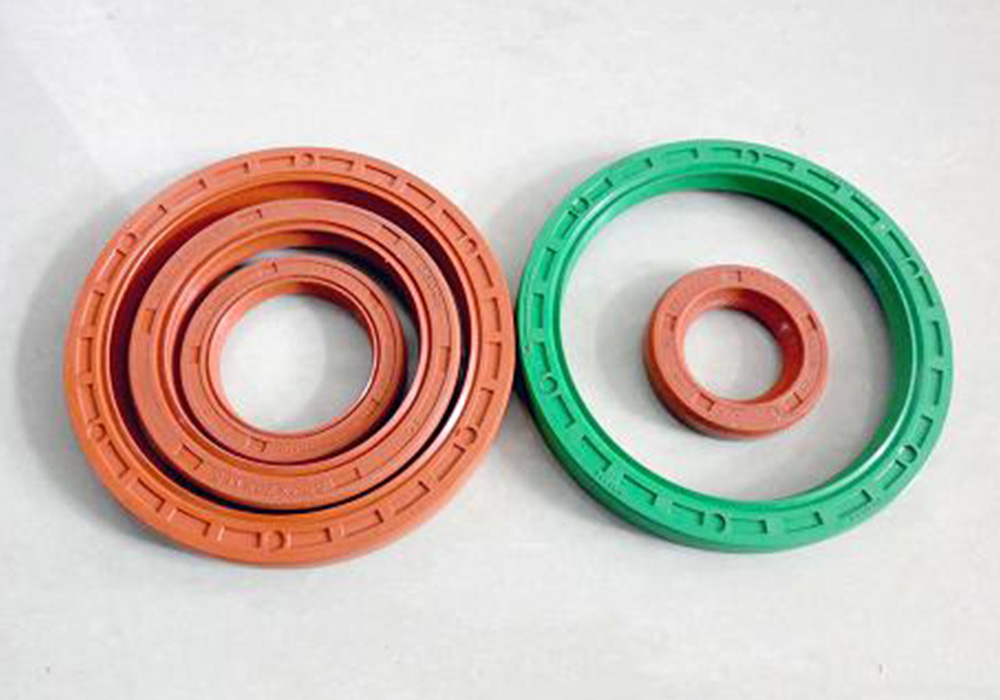

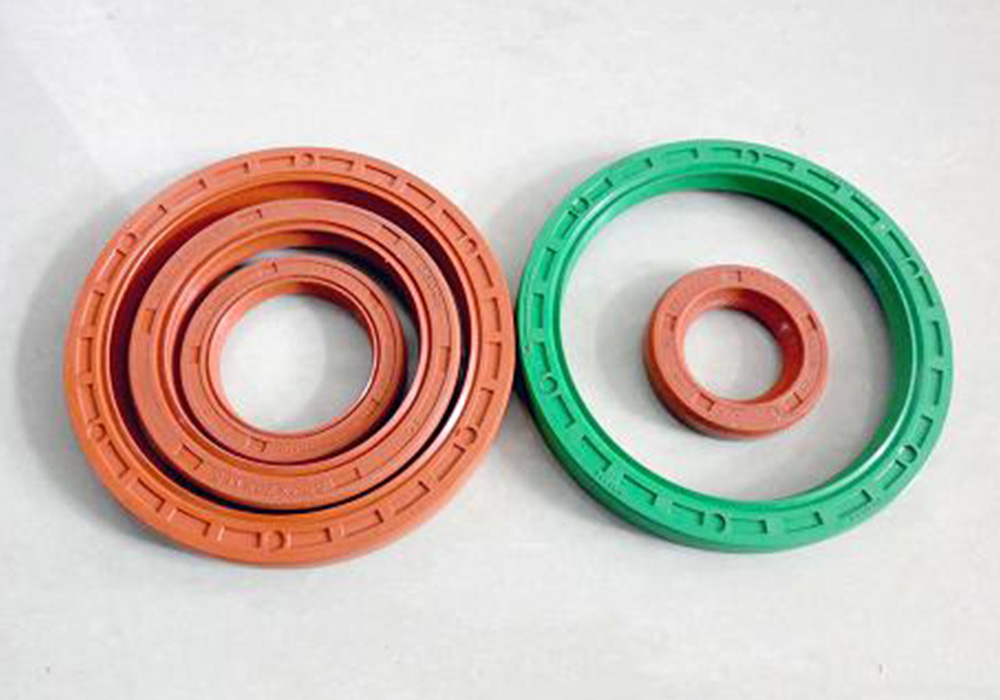

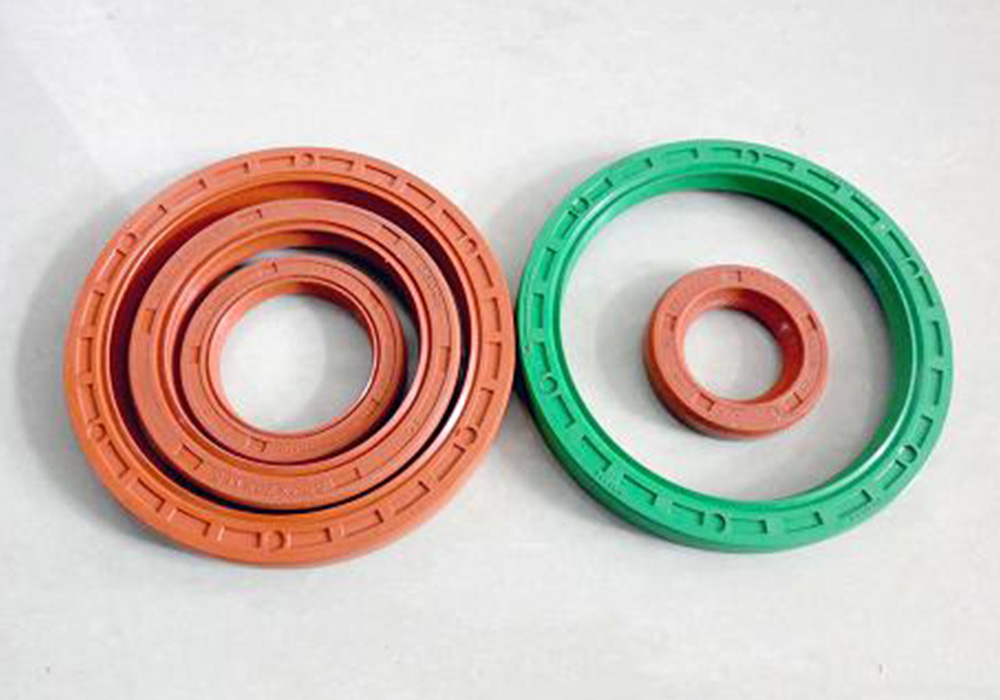

Two-way hydraulic oil seal product introduction:

Two-way hydraulic oil seals are also known as counter-hydraulic oil seals. These oil seals are more resistant to pressure than some oil seals previously known. Because they are both pressure-bearing, they are also called two-way hydraulic oil seals.

Two-way hydraulic oil seal sealing solution is not strict oil leakage:

1. Understand and distinguish the basic knowledge of counterfeit goods and purchase high-quality, standardized hydraulic oil seals.

2. When installing, if the shaft diameter is low, such as rust, corrosion, burr, etc., it needs to be polished with fine sand cloth or oil stone; apply cleaning gear to the matching part of the skeleton sealing lip or shaft diameter. Oil or grease. Apply sealant to the outer ring of the seal ring, wrap the pin hole on the shaft with hard paper to prevent scratching the skeleton seal skirt, and use the common tools to insert the skeleton seal inward and insert it into the shaft. To prevent the skeleton seal from deforming or squeezing the yellow, it is invalid; if the skirt is reversed, the yellow is falling off and the skeleton seal is tilted, be sure to remove it and reload it. It should be noted that when the shaft diameter is not worn and the oil seal spring is elastic, it is not necessary to tighten the inner yellow.

3. The skeleton seal used in the automation equipment is usually in extreme conditions, the temperature difference between the ring mirror is large, the floating dust is too much, and the vibration of the equipment repeatedly makes the reaction force of the mechanical parts and supports continuously change, and it is necessary to check, nurse and protect.

4. If the shaft diameter and the bearing shaft are seriously damaged; the skeleton seal plastic embrittlement or the yellowing failure, etc., should immediately repair and replace the relative components.

5, for the abnormally hot components or the total range should be immediately fault detection; to prevent the machine from overspeed, high load operation, to avoid the temperature rise of the skeleton seal skirt, plastic embrittlement, early damage to the skirt.

The above is a brief introduction to the introduction of the two-way hydraulic oil seal and the solution of the two-way hydraulic oil seal is not strict, I hope to help everyone.